This part solves a problem...

...I hope so.... I always had the problem that the elevator was a bit jumpy. I had to move the stick quite a bit until something happened and then it happened too quick and too much. It felt like the elevator was sticking somehow.

After a bit of thinking, I found the problem; the potentiometer travel was too short. The interface I use makes 128 steps at full travel of a 10kOhm potentiometer. But I only use about 20 degree of a 300 degree pot and this is after the calibration eight to ten steps. No wonder that my elevator reacts jumpy.

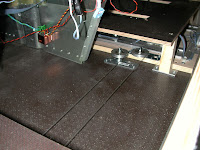

I solved the problem like in the old days. A piece of fishing line runs around a wheel on the pot axis and if the wheel has the right diameter, the travel of 8cm makes 300 degrees of turn. I will see if it works when it is installed. The brown wheel by the way, is an original part from the Connie cockpit. It was used inside the throttle console to guide the steel cables of the trim wheels.

Today I noticed that it becomes difficult to work on the simulator since all the parts are installed. I have to crawl under the floor, bend myself around the seats... I think this is the way real aircraft technicians have to work. Not always an easy job.