4.4.2006 a bit later...

It works! Now I can tell you the story of "Project 2".

Project 1 is of course the complete, real and flying Breitling Super Constellation, one of only three left in airworthy condition in the whole world. The Australians have one, the Americans have one... and the Swiss have one too. More infos about that project at www.superconstellation.ch

But this blog here is about Project 2, the Super Constellation Flight Simulator, built with real 50 years old parts. Where shall I start with the story.... well let's start with Francisco. Francisco is a Pilot from Geneva who loves to spend his holidays in South America or the Carribean just to fly old airplanes.

He flies with meat over the Andes or with fruits from Santo Domingo to Florida just because... just for fun.

The first Super Connie he flew was the HI-548CT of the dominican air transport company AeroChago. This airplane was destroyed by hurricane George in 1998. The wind lifted another airplane ( a Curtiss Commando) from ground and threw it onto the Connie.

1999 Francisco bought the wreck and removed all the usable parts such as the entire cockpit.

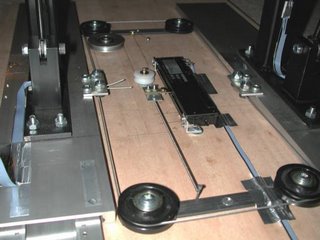

Well... these parts lie now in my workshop awaiting their restauration and the assembly to a flight simulator.

Beautiful but without a function... the trimmers. I will not convert them to work with the simulator. They are looking good and that's fine.

Beautiful but without a function... the trimmers. I will not convert them to work with the simulator. They are looking good and that's fine.